How Ball Mills Work (Engineering and Mining) YouTube

Jun 20, 2019· Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ball...

WhatsApp)

WhatsApp)

Jun 20, 2019· Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ball...

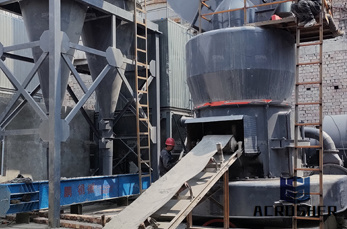

function of ball mill in cement manufacturing process. ball mill used for cement manufacturing process. Ball mill Wikipedia. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silies, refractory material, fertilizer, glass ceramics, etc. as well as for ...

Introduction And Functioning Of Ball Mills Israel. Mechanochemical synthesis includes protocols that use laser ablation and highenergy ball milling techniques while the chemical synthesis consists of solgel hydrothermal coprecipitation and. know more:If you want to know more product information.

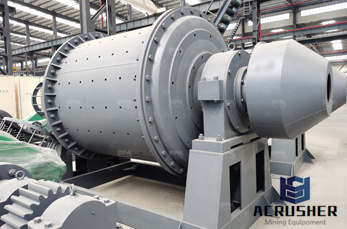

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft. This type of mill uses the same principle as a VSI crusher.. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a ...

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Ball Mills Introduction Caesar Mining Equipments. Introduction of ball mills ball mill ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds ...

Introduction To Ball Mill. Introduction Of Grading Steel Ball For Ball Millcement The main function of steel ball in ball mill is to impact and break the material, and bring about certain grinding, the purpose of grading steel balls is to meet the requirements of these two aspects ...

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles ...

introduction and functioning of ball mills Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which . ball mills introduction introduction and functioning of ball mill . Energy saving ball. Get Price

Function Of Ball Mill With Animation. Weve already made a ball, now lets make it order to do so, well create a draw function which wipes the screen, draws the ball, then updates its current use a call to setintervalfunction, timeout in the init function to tell the browser to run our draw function every 10 milliseconds, creating the illusion of movement.

Function Of Ball Mill In Making Cement Café Genuss. Improving Mill Shoe Bearing Reliability And. So, this week well discuss mill shoe bearings and how to enhance their reliability and ball cement ball mill is designed to grind clinker, gypsum and for the drying of cement is a component in the cement making ball mills are typically ...

I. Introduction . Grinding in ball mills is an important technological process applied to reduce the ... The breakage functions are shown in the third column and the ... yang mencerminkan ...

functioning of ball mill lubrication system function of a trunnion on lube system on mills. functioning of ball mill lubrication system bmdcollegein an optional accessory offered for our ball mills is the load cell system, Trunnion Bearing Lube System, fully automatic function, [Online Chat] functioning of ball mill lubrication system ugcnetnicin.

The Drum Mill TM 500 is a laboratory ball mill designed to grind large sample volumes up to 35 l. It accepts initial feed sizes of up to 20 mm and can achieve grind sizes down to 15 µm by friction and impact. Hard, brittle or fibrous samples are pulverized in the 150 l drum filled with 80 kg grinding balls.

Introduction And Functioning Of Ball Mills Henan . Grinding in ball mills is an As a construction a ball milling device usually consists of a cylindrical vessel mounted on an equipment used to load the starting material feeders and the system for discharging the output. Read More Working Principle Of Ball Mill .

Mixer Mill MM 500 vario Function Principle The grinding jars of the mixer mill MM 500 vario perform radial oscillations in a horizontal position. The inertia of the grinding balls causes them to impact with high energy on the sample material at the rounded ends of the grinding jars and pulverize it.

Grinding in Ball Mills: Modeling and Process Control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics.

Dec 23, 2013· Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: ''Ball milling is a method used to break down the .

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

Introduction And Functioning Of Ball Mills. Introduction and functioning of ball mills ball millwikipedia the free encyclopedia a ball mill is a type of grinder used to grind and blend materials for use in more info introduction ball miller machine gatewaypreschoolorg introduction and.

In a ball mill circuit, the "output" can be defined as the production rate of fines of the circuit. As for any output, ball mill circuit output is a function of both its inputs and efficiencies. There are two "inputs" to a ball mill circuit: the ore fed to the circuit and the power delivered by the grinding mill.

Introduction of grading steel ball for ball millcement. The main function of steel ball in ball mill is to impact and break the material and bring about certain grinding ore the purpose of grading steel balls is to meet the requirements of these two quality of crushing effect directly affects the grinding efficiency and ultimately affects the output of the ball r the crushing requirements can ...

Principle Of Functioning Ball Mill Pdf. Mineral Processing Equipment: principle of functioning ball mill pdf A type of mining equipment that can trigger the development and change of the beneficiation technology main core machines are ball mills, rod mills.

WhatsApp)

WhatsApp)