Planetary Roll Off YouTube

Oct 29, 2009· Planetary Roll Off General7447. Loading... Unsubscribe from General7447? ... housingless rolling mill animation Duration: 7:29. Chen Ying Maplesail 71,851 views.

WhatsApp)

WhatsApp)

Oct 29, 2009· Planetary Roll Off General7447. Loading... Unsubscribe from General7447? ... housingless rolling mill animation Duration: 7:29. Chen Ying Maplesail 71,851 views.

Sep 30, 1975· The present invention relates to metallurgical machinebuilding and more particularly to planetary rolling mills. Known in the art is a planetary rolling mill comprising a working stand whose housing accommodates planetary (rolls) assemblies, each assembly being made up of an idle backup roll whose drive axle is arranged in bearing chucks and of a set of work rolls spaced along the .

As the hydraulic wheel was first used in grist mills, all the factories were later also called "mills". Over the years, the milling technique in the grist mills has been adjusted and perfected. Agostino RAMELLI depicted the mechanism of a grist mill in his book "Le diverse et artificiose machine" in 1588.

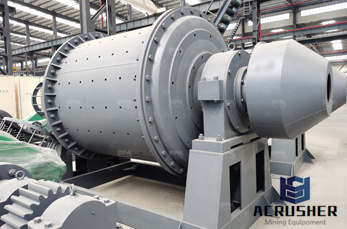

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

FIELD: tube rolling production, in particular, cold rolling of tubes. SUBSTANCE: working line for tube cold rolling mill has working stand with stationary power frame, movable cassette and drive for reciprocating movement of planetarycrank type cassette with straight linear movement of ratchet in vertical plane extending through rolling line.

Universal Rolling Mill Diagram bmjeducationorgin. Patent US Universal rolling mill , Try the new Google Patents,, and a Fig 10 is a diagram of the plant referred to, In a universal rolling mill.

(with the planetary mill) – ГНЦ РФ "ВНИИМЕТМАШ им . (with the planetary mill) Main advantages of casting and rolling units as compared with conventional bar rolling plant: .Rolling diagram in the planetary stand. »More detailed

planetary rolling mill with diagram . Rolling schematic view. Rolling visualization. (Click on image to view animation.) In metalworking, rolling is a metal forming process in which metal stock is passed through one ... Most steel mills have rolling mill divisions that convert the semifinished casting products into finished products.

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process.

Planetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls.

Types Of Mills Used for The Rolling of Plates PlateMill Design The Levelling of Plates The Cooling, Marking and Cutting of Plates The Ultrasonic Inspection and Gaging Of Plates Modern PlateMill Installations CHAPTER 11 HOT STRIP MILLS Introduction Steckel Hot Mills Planetary Mills NIIR Project Consultancy Services (NPCS) 7/9

60 YEARS OF ROLLING MILL TECHNOLOGY By Ford B. Cauffiel . 2 ... When most people think of a rolling mill, they visualize sizable machinery in ferrous (iron, carbon steel and stainless steels) and nonferrous (copper, brass, lead, etc.) integrated or electric arc furnace (EAF)

Tags Metal Processing Machinery, Rolling Mills; Four Types of Rolling Mills. In the past two articles we briefly outlined rolling mills, and also expounded on three different types. In this article, we will finish the series outlining the differences between a fourhigh rolling mill, cluster rolling mill, continuous mill and a planetary rolling mill.

A Planetary Ball Mill for rapid fine crushing of soft, hard, brittle and fibrous material to end fineness <1µm Quick and easy to clean Rapid fine crushing Easy exchange of grinding jars and balls Grinding jars and balls made from a wide range of materials available Grinding jar volume up to 500cc Progr. control End fineness < 1µm CEcertified Planetary Ball Mills for fine grinding of soft ...

Jul 01, 2013· Continous action planetary mills. Planetary mills for nanogrinding, ultrafine and submicron grinding.

Planetary Rolling Mills: The Planetary Mill is a medium output mill for rolling of steel strip. Its output is less than continuous mills of many stands but more than the reversing twohigh or the threehigh mill. This mill can be used to roll all metals but it is especially useful for those which have low ductility.

Find Planetary Rolling Mills related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Planetary Rolling Mills information. ... Schematic diagram of planetary roll mill . Method for the contactless measurement of process parameters in a continuous rolling .

May 02, 2017· Planetary Rolling Mill: In this type of rolling machine, a large backup roller is surrounded by various numbers of planetary working rollers as shown in figure. Each planetary roll gives constant reduction. It is used to reduce large thickness in single pass of steel strip. Its rolling capacity is more than cluster machine but less than tandem ...

PDF | Pipe rolling process using the planetary rolling mill for AISI 304 stainless steel has been studied by using finite element method. Mannesmann method using threeroll is applied to this ...

The rolling process is shown in Fig. : Rolling is done both hot and cold. It is accomplishes in rolling mills. A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc. Rollers may be plain or grooved depends upon the shape of rolled product.

planetary rolling mill with diagram BINQ Mining. Planetarytype Rolling Mill For Nonflat Products – Patent . FIG. 3 is the schematic diagram of the whole system for implementing the . passing through the planetary rolling mill are similar to those derived by rolling . »More detailed. live chat

Hot Rolling of Metals: With Diagram | Industries | Metallurgy. ... Planetary Rolling Mills: It has been observed that rolling force is conveyed more effectively in deforming the metal by small diameter rolls than by bigger diameter rolls because of the reduced area of contact of smaller rolls which produces higher rolling pressures. Planetary ...

Synthesis of Nanomaterials by High Energy Ball Milling W. Cao . Skyspring Nanomaterials, Inc. ... Planetary ball mill is a most frequently used system for mechanical alloying since only a very small amount of powder is required. ... Thus friction resulted from the hardened milling balls and the powder mixture being ground alternately rolling on ...

A NEW GEARBOX GENERATION FOR VERTICAL ROLLER MILLS By: Dr. Roger Raeber, Vice President Engineering, MAAG Gear AG Ulf Weller, Senior Design Engineer, MAAG Gear AG Rocco Amato, Head of Mill Gear Engineering, MAAG Gear AG Drive trains of vertical roller mills are usually equipped with heavy duty gearboxes with a horizontal input

WhatsApp)

WhatsApp)