Hamilton College closer to buying Rod Mill parcel

The City of Rome has transferred a small portion of the Rod Mill parcel on Harbor Way to the Rome Industrial Development Corporation (RIDC), one of the last steps before the property is sold to ...

WhatsApp)

WhatsApp)

The City of Rome has transferred a small portion of the Rod Mill parcel on Harbor Way to the Rome Industrial Development Corporation (RIDC), one of the last steps before the property is sold to ...

Power Engineering is the definitive online resource for power generation professionals. Stay up to date with the latest industry developments.

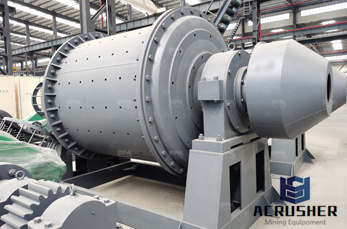

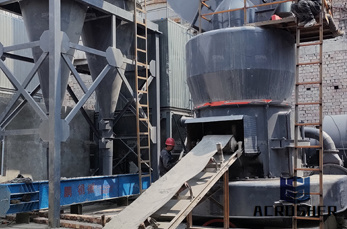

The rod mill is an asynchronous motor connected through a reducer and a pinion gear, which directly drives the surrounding large gears to decelerate rotation, drives the rotation part to rotate, and the barrel body is filled with an appropriate grinding medium—steel rods, and the grinding medium is subjected to centrifugal force and friction force.

Rod mill is roughly as same as the ball mill, but there are three distinct differences:. 1. The rod mill normally uses the steel rod of 50100mm as the medium, and the ball mill uses steel ball as the medium. The length of steel rod is 25 to 50mm shorter than the barrel body, the load of rod quantity is 35% to 45% of the effective volume of the rod mill.

UGI manufacturers bar mills, wire rod mill and section mills for angle, channel, beam and flats and narrow strip mill (upto 500mm). UGI has a technical collaboration with Sead Steel, Turkey to manufacture rolling mill to produce 5,00,000 tons per technology used is "SLIT ROLLING" which is a proven in European countries and a new ...

(D) 15 Strand Rolling Mill; Type: Y Type, 3 Rolls: No. of Rolling Mill stand: 15 Nos. Main motor required: AC frequency drive speed 150 to 1500 RPM 225 KW: Rod output die: mm., mm., 12 mm., 15mm. Normal crosssec. of castbar: 1150 Sq. mm. Cooling Oil Required: 300 to 500 Liter / Hr. Lubricant Oil Required: 300 to 500 Liter / Hr ...

Work With Us. We are nationally recognized and locally preferred. We would love to work with you on your next project. Contact Us

The two onestrand highspeed mills will roll wire rod in diameters from to 25 millimeters and rebars in diameters between 6 and 14 millimeters at rolling speeds of up to 105 m/s.

The building structural system was altered accordingly. The new mill and the structural alternation were carried out during the spring of 1984. Since then, the new mill and the structure have performed satisfactorily. Key words: rod mill, foundation, vibrations, soil springs, dynamic analysis, structured response, dynamic amplitude ratios.

Congratulations! 900tpd rotary kiln, 2x600tpd twinshaft PFR kiln, 2745 rod mill contracts . Previous; Next; Congratulations! 900tpd rotary kiln, 2x600tpd twinshaft Pfr Kiln, 2745 rod mill contracts. after several round bids, MER finally win three projects for three calcium and iron steel customers: 900tpd rotary kiln, 2x600tpd twinshaft Pfr Kiln, 2745 rod mill contracts

BSRM is one of the leading steel Re Rolling mills in Bangladesh. As a prominent steel manufacturing company, it has been offering strength, safety and sustainability.

Engineering News Online provides real time news reportage through originated written,video and audio material. Each week,an average of 240 899page impressions are generated by over 64 719 online ...

This website uses cookies to improve your experience. We''ll assume you''re ok with this, but you can optout if you Read More Read More

For news about developments with the website and news about the engineering and maker industry! Tools Calculators. Our list of online calculators is growing! click here to see what we currently have available. Contact Us! Something you want to get in touch with us about? Send us a message! we''d love to hear from you.

Work is underway on the project at our Scunthorpe Rod Mill and, once completed, the new laboratories will further enhance British Steel''s testing facilities. Richard Sims, British Steel Managing Director Wire Rod, said: "We''re continually looking at ways to improve our products and the new laboratories will play an important role in ...

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll ...

UGI Engineering Works Pvt. Limited India supplier of ROLLING MILL, BAR ROLLING MILL, WIRE ROD MILL, CHANNEL ROLLING MILL

Get the latest news and information on genetic engineering and biotechnology including analysis, features, webinars, podcasts, and more.

Production News. Double rotor rod mill from pakistan. Size reduction visual encyclopedia of chemical engineering. size reduction in attrition mills occurs through the scraping of one surface against another particles scrape against each other or against a rigid face types of tumbling mills include rod mills ball mills and tube mills a colloid mill rotor is an intermeshing rotor used for the size.

I want to get the latest chemistry news from CEN in my inbox every week. ACS values your privacy. By submitting your information, you are gaining access to CEN and subscribing to our weekly ...

CHEMICAL ENGINEERING. Mechanical Operations. Rod mills employed for grinding_____? Rod mills employed for grinding_____? A. Employ a steel shell having L/D ratio of to B. Is useful for handling sticky materials C. Employ steel rods of 212 cms diameter extending over full length of the mill ...

(D) 15 Strand Rolling Mill; Type: Y Type, 3 Rolls: No. of Rolling Mill stand: 15 Nos. Main motor required: AC frequency drive speed 150 to 1500 RPM 225 KW: Rod output die: mm., mm., 12 mm., 15mm. Normal crosssec. of castbar: 1150 Sq. mm. Cooling Oil Required: 300 to 500 Liter / Hr. Lubricant Oil Required: 300 to 500 Liter / Hr ...

Two GMBZ2445 rod mills designed by Luoyang Dua have been put into trial operation in Singapore recently, and the equipment runs well. The equipment is used for limestone processing and the terminal materials for desulfurization operations in power plants. The rod mill adopts sliding bearing support, feeding hopper and surrounding discharge.

Normal operation rod mill built on timely maintenance and repair, in order to make the normal operation, lubrication equipment must be done, in addition, but also to grasp the main control point of rod mill. 1. First, the rod mill maintenance to take the right approach, at the same time, but also to observe rod mill gearbox bearing temperature ...

WhatsApp)

WhatsApp)