How Does Bitcoin Mining Work? Investopedia

Nov 21, 2019· Bitcoin mining is the process by which new bitcoins are entered into circulation, but it is also a critical component of the maintenance and development of the blockchain ledger.

WhatsApp)

WhatsApp)

Nov 21, 2019· Bitcoin mining is the process by which new bitcoins are entered into circulation, but it is also a critical component of the maintenance and development of the blockchain ledger.

Gold can be concentrated and recovered by applying different gold refining process methods and the final product has variable quality. In this way, it is necessary to have a better marketable product so that the incomes can be improved.

Occasionally, the amalgamation process does not collect as much gold as anticipated. This type of result usually occurs when the formation of amalgam is inhibited due to poor contact between the gold and the mercury. This happens most commonly when the gold is very fine or when it is tarnished by a surface or film.

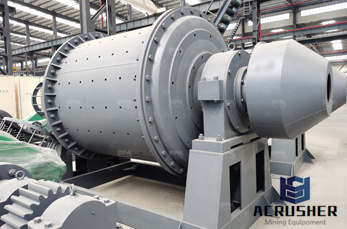

Removing the goldbearing rock from the ground is just the first step. To isolate pure gold, mining companies use a complex extraction process. The first step in this process is breaking down large chunks of rock into smaller pieces. At a mill, large machines known as crushers reduce the ore to ...

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the .

Nov 07, 2019· How to Apply Gold Leaf. Gold leaf is gold that''s been hammered into a thin foil and is usually sold in sheets or rolls. It''s often used to decorate picture frames, books, and even food. Gilding is the process of applying gold leaf. It...

Gold, recognizable by its yellowish cast, is one of the oldest metals used by humans. As far back as the Neolithic period, humans have collected gold from stream beds, and the actual mining of gold can be traced as far back as 3500 , when early Egyptians (the Sumerian culture of Mesopotamia) used mined gold to craft elaborate jewelry, religious artifacts, and utensils such as goblets.

Editor''s Note: In our last article, Calla Gold, a Santa Barbara jeweler specializing in custom jewelry design and jewelry repair, described gold plating and its best practices. In this article, she describes the stepbystep process. How Gold Plating is Done, Step by Step by Calla Gold . Gold plated – sometimes called electroplated – items are made with a layer of gold on the surface ...

Apr 24, 2017· Dr. F. B. Miller of the Sidney Mint created a process to purify gold using chlorine, which forms chlorides with silver and other ore impurities but leaves gold unaffected. The refiner places the ore in clay pots, heats the vessels in a furnace and pumps chlorine gas into each pot.

Apr 24, 2017· According to Hoover and Strong, a refiner and manufacturer of precious metals, they produce 98 percent pure gold using the Miller process. After a sample of treated impure gold has been tested in a lab for purity, the gold is melted in a furnace, then chlorine is bubbled through the liquid.

Gold Carbon In Leach Plants Updated January 2017. Gold Processing Plant, Carbon In Leach (CIL) Plant. A Carbon In Leach Gold Recovery Plant. This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant.

Nov 26, 2019· The gold refinery can sell the gold to other companies like recycled metal suppliers, jewelers, and electronics manufacturers. The processes at a gold refinery can vary. Processing precious metals requires the use of caustic and toxic chemicals, and historically pollution was a problem with many refineries. Some companies pride themselves on ...

how does a gold wash plant work How Does Gold Mining Work? (with pictures) wiseGEEK. May 20, 2016 Sediments are collected and placed in the pan. Water is used to wash out the lighter materials, leaving the heavier metals, hopefully gold, in the. Business offer

Sep 01, 2011· Gold mines produce rough gold, called a dore bar. These bars are typically about 80 percent pure gold. The gold is then sent to a refinery, where it is refined into gold .

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth''s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions ...

Gold cyanide is adsorbed into the pores of activated carbon, resulting in a process solution that is devoid of gold. The loaded carbon is heated by a strong solution of hot caustic and cyanide to reverse the adsorption process and strip the carbon of gold. Gold is then removed from the solution by electrowinning.

The process design of gold leaching and carboninpulp circuits 14 JANUARY/FEBRUARY 1999 The Journal of The South African Institute of Mining and Metallurgy Figure 2—The CarbonInPulp (CIP) process Figure 1—ComputerAided Process Engineering (Cape) Define ... Process does not work Regenerated carbon Fresh carbon Gold Steam Eluant Cyanide ...

How does the gold futures exchange work? ... For simplicity''s sake, imagine a jeweler needs 100 ounces of gold to make four hundred gold rings. The process may take him .

Jun 02, 2010· This video was produced by Newmont Mining Corporation and gives a general overview of gold mining in Nevada from extraction to reclamation.

Gold panning, or simply panning, is a form of placer mining and traditional mining that extracts gold from a placer deposit using a pan. The process is one of the simplest ways to extract gold, and is popular with geology enthusiasts especially because of its low cost and relative simplicity.

Oct 20, 2014· Leaching gold with a cyanide solution remains the most widely used hydrometallurgical process for the extraction of gold from ores and concentrates. Despite the difficulties and hazards of working with cyanide, no other process has yet been proven to be an economic viable alternative.

Apr 24, 2017· Gold is purified by means of a smelting process, which utilizes pressure, high heat and chemicals to accomplish the task. Like any metal that appears naturally in the earth, there are impurities that must be removed. Removing minerals and other impurities allows gold to be used in its purest form, which is necessary ...

Recent developments in dry washing equipment have made it possible for a one or twoman operation to work larger volumes of dry placer ground without water, and obtain good results in gold recovery. Dry processing recovery systems generally use air flows to do the same job that water does in wet recovery systems.

A mercurygold amalgam then is formed because gold will dissolve in the mercury while other impurities will not. The mixture of gold and mercury is then heated to a temperature that will vaporize the mercury, leaving behind the gold. This process does not result in gold that is pure, but it does eliminate the bulk of the impurities.

WhatsApp)

WhatsApp)