How to cut concrete pavement slab with a grinder without ...

Apr 17, 2017· How to cut concrete pavement slab with a grinder without proper tool for cutting. ... This video is showing how to cut a concrete pavement slab by using a standard grinder.

WhatsApp)

WhatsApp)

Apr 17, 2017· How to cut concrete pavement slab with a grinder without proper tool for cutting. ... This video is showing how to cut a concrete pavement slab by using a standard grinder.

ACME Concrete Paving grinding and rehabilitation division is equipped to restore roadways and add years of service to existing highways. As the premier concrete paving preservation and grinding company, in the Northwest, and provide all the tools and skills necessary to complete the most demanding projects.

Deeper diamond grinding will expose the coarse aggregate in the concrete pavement. Softer coarse aggregates that are exposed may polish and result in lower skid numbers. The department developed special specifications for diamond grinding.

Slippery when wet. But it is becoming common to do something more than warn motorists. Sawing grooves into pavements greatly reduces wet weather skidding accidents on roads and airports. During the past 15 years more than 5 million square yards of highway pavements have been grooved and accident records verify that grooving creates safer highways.

Diamond grinding . Diamond grinding is the removal of hardened Portland cement concrete (PCC) through the use of closelyspaced, diamond saw blades mounted on a rotating drum. Diamond grinding is used for the removal of bumps or scallops that cause poor ride quality and to restore surface texture, improving overall friction.

diamond grinding shall be completed on any given section prior to opening that section to other than construction traffic, unless approved by the OwnerAgency. When diamond grinding is used to retexture an existing concrete pavement, any concrete pavement preservation activities, except for joint sealing, shall be completed prior to any ...

SASE Signature Floor System.. This system is designed for industrial, commercial, retail and residential concrete floors. The result of this system is higher quality and more durable polished concrete floors.

Need to leave your concrete with a polished finish? Grinding concrete is the process used to remove high spots and imperfection on the concrete surface. The Diamond Tool Store Carries some of the most aggressive Cup wheels and Concrete grinding segments in the market. Weather you need concrete pads, grinding wheels or segments the diamond tool ...

Sunbelt Rentals offers Concrete Floor Grinders for leveling, smoothing, and cleaning concrete surfaces. View our Concrete Floor Grinders today.

Advantages of Diamond Grinding Concrete Pavement, Know More. Diamond grinding is a concrete pavement restoration process that renews a worn or slightly irregular surface Diamond grinding can potentially remove or reduce some pavement deficiencies such as joint faults resulting from minor pavement settlement, worn pavement from wheel rutting, warped slabs, and a rough surface texture...

Diamond grinding is a concrete pavement restoration process that renews a worn or slightly irregular surface. Diamond grinding can potentially remove or reduce some pavement deficiencies such as joint faults resulting from minor pavement settlement, worn pavement from wheel rutting, warped slabs, and a rough surface texture.

WSDOT is investigating the following pavement grinding options to reduce the noise from older concrete pavements. Next Generation Concrete Surface (NGCS) is a new grinding method that has produced the quietest concrete pavements in other states. Conventional diamond grinding (CDG) reduces noise from older concrete pavements.

The Contract Price per square yard (meter) for grinding concrete pavement is full compensation for furnishing labor, materials, tools, equipment, and incidentals grinding the existing surface, removing residue, and cleaning the pavement according to these Specifications and as shown on the Plans. Payment will be made under:

Rent a Concrete Grinder 10" from your local Home Depot. Get more information about rental pricing, product details, photos and rental locations here. ... Tool, Truck Equipment Rental Concrete Tools Concrete Grinder 10" EDCO | category #09 group #980. Concrete Grinder 10" Description Model # 50200HD ... Visit the Tool Rental Center to ...

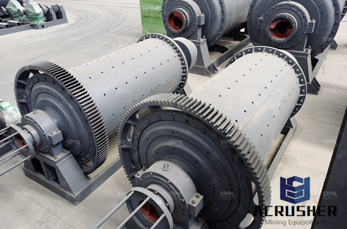

Grinding Tool For Concrete Pavement; Grinding Tool For Concrete Pavement. Our company has been devoted to mining machinery for 40 years. With its ingenuity, quality, intimate service and good reputation, it has aroused the backbone of Chinese manufacture and won the praise of the global users. We also choose us as a successful enterprise and a ...

Jul 02, 2014· Diamond grooving and grinding is a concrete pavement preservation technique that corrects a variety of surface imperfections on concrete pavements, and .

Diamond grinding is a pavement preservation technique that corrects a variety of surface imperfections on both concrete and asphalt pavements. Most often utilized on concrete pavement, diamond grinding is typically performed in conjunction with other concrete pavement preservation (CPP) techniques such as road slab stabilization, full and ...

Publication Details Concrete Pavement Rehabilitation Guide for Diamond Grinding . Primary Topic: Pavement Rehabilitation. Description: Document briefly summarizes diamond grinding technique for rigid pavement restoration and discusses the concept, equipment, advantages, design considerations, construction, performance and document also provides an example guide specification.

Diamond grinding is a concrete pavement restoration technique that corrects irregularities such as faulting and roughness on concrete pavements. Diamond grinding should be used in conjunction with other Concrete Pavement Rehabilitation (CPR) techniques. A full CPR job can restore structural and functional capacity of a pavement to acceptable levels

Diamond grinding is a pavement preservation technique that corrects a variety of surface imperfections on both concrete and asphalt pavements. Most often utilized on concrete pavement, diamond grinding is typically performed in conjunction with other concrete pavement preservation (CPP) techniques such as road slab stabilization, full and ...

Grinding Scarifying Equipment. Graco''s grinders and scarifiers are the preferred choice of contractors who need to remove pavement markings, perform inlay grooving, and smooth uneven surfaces. Our pavement marking removal equipment delivers unmatched results and is designed to handle the daily demands of professional contractors.

Dec 01, 2012· Concrete grinding is a means of preserving pavement by removing surface irregularities and imperfections. This sometimes includes concrete leveling to make the surface more durable, or the use of a concrete grinder to smooth a rough surface. Roads absorb a .

Diamond Grinding Concrete Pavement 1. Description. Diamond grind existing concrete pavement surfaces and remove resulting residue at locations shown on the plans or as directed. 2. Equipment. Provide machinery, tools, and equipment necessary for proper execution of the work. Use grinding .

After grinding away the imperfections, it''s possible to produce a smooth, polished surface from a worn down slab of pavement or concrete. The Biggest Benefits of Concrete Diamond Grinding Smooth Surfaces. First of all, one of the more immediate benefits and results of grinding concrete .

WhatsApp)

WhatsApp)