ball mill for coal fired power plant working

The practical use of ring–ball coal mill model signals ... during operation of power unit and to obtain (in accordance. Get price Grinding Pulverizing Mills, 102 Lubrication Engineers International

WhatsApp)

WhatsApp)

The practical use of ring–ball coal mill model signals ... during operation of power unit and to obtain (in accordance. Get price Grinding Pulverizing Mills, 102 Lubrication Engineers International

Grinding mill in cement production is to produce limestone or other raw materials to about 90 passing 90 microns in a dry circuit grinding occurs at the beginning and the end of the cement making process production costs and environmental concerns are emp,Use Of Coal In Cement Making Newest Crusher Grinding Mill.

Jul 01, 1984· Experimental size distributions for coal ground in O_98 m LD. pilotscale airswept ball mill fitted with a twincone classifier 259 ing to a frac''tional filling of the mill volume by the bed of balls of J = 0_2, using a formal porosity of for the ball bed (290 lb/ft3)_ The dry mass of coal used was 122 g; assuming an apparent specific ...

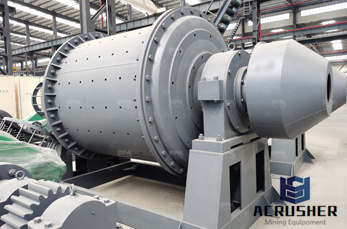

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

The advantages and disadvantages of ball mill The advantages and disadvantages of ball mill. The advantages of ball mill: 1. ... With a large grinding ratio, ...

disadvantage of climb milling . bridger coal phone directory – Grinding Mill China bridger coal phone directory brinquedo carrinho mega crusher com controle 4x9 ball mills for sale in gauteng south africa advantages and disadvantages of upcut milling does the raw material provider crush the feldspar wemco mineral processing equipment Read ...

[randpic] ball mill coal crushing ball mills crusher machine in coal plants . Ball mill machine is an effective mill rock crushing machine for grinding various of material, general term as rock crusher, coal crusher, laboratory crusher, cement crusher, etc. Ball mills grinding task can be done under dry or wet condition, good at both of wet milling and dry milling. in addition

The ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill. These mills .

The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls. Ball mills grind material by impact and attrition. The degree of milling in a ball mill is influenced by; a. Residence time of the material in the mill chamber. b. The size, density, and number ...

The ball mill work index laboratory test is conducted by grinding an ore sample prepared to passing mm (6 mesh) to product size in the range of 45150 µm (325100 mesh), thus determining the ball mill work index (Wi B or BWi). The work index calculations across a narrow size range are conducted using the appropriate laboratory work ...

The Drum Mill TM 500 is a laboratory ball mill designed to grind large sample volumes up to 35 l. It accepts initial feed sizes of up to 20 mm and can achieve grind sizes down to 15 µm by friction and impact. Hard, brittle or fibrous samples are pulverized in the 150 l drum filled with 80 kg grinding balls.

Disadvantage Of Horizontal Grinding Ball Mill. Disadvantage of metal grinding ball mill processt is a ball milling process where a powder mixture placed in the ball mill is subjected using different apparatus, namely, attritor, planetary mill or a horizontal ball mill phase are the other disadvantages of high energy ball milling process.

crushing the coal into powder using ball mills. coal ball mill used in power plant ball grinding mill crushing coal alstom both our ball mill for direct firing systems disadvantage of using ball mill in coal . Get Price. Get Price; Longlasting coal mill for efficient grinding FL. A compact coal mill solution for grinding virtually any type of ...

Advantages And Disadvantages Of Small Ball Mill. small ball mill is mainly used for grinding all kinds of coal with different hardness to prepare qualified coal powder fuel for powder plant generator boilers and the relevant industrial departments, which can also be used in cement plant and other related industrial sectors to grind other materials. advantages of small ball mill

tube and ball mill coal pulverizer ukrainian grinding mills,Various Types of Pulverizers Coal Pulverizers may be classified by speed Low Speed Ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder Due to its shape it is called a tube mill and due to use of grinding balls for crushing it is called a ball mill or both terms as a ball

Nov 27, 2018· Ball Mill Disadvantage Ball mill Use Ball mill construction Ball mill Working We hope you will like this video. If you really enjoyed this video, please subscribe to this channel and support us to ...

Ball mill Wikipedia how coal mill grinding process,A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, The ball mill is used for grinding materials such as coal, pigments, and feldspar for pottery.

The ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill. These mills .

mine grinding vrm or ball mill liverpool turismoit. advantages of vrm over ball mill manveesinghin advantages of using ball mill over vrm 9416 vertical roller mill advantages ZCRUSHER advantages of using ball mill over vrm 9416 advantages of ball mill over a vertical mill Cement grinding Vertical roller mills versus ball mills with an ability to dry grind and classify within a single unit ...

Elements of Coal Grinding System: Mill Feeding: Consists of following activities Coal Crusher: Generally, require when ball mill is used for grinding and raw coal size is on higher side(>25mm). Conveying to Hoppers: Covered belt conveyors, horizontal or inclined are most suitable and commonly used for conveying. Metal Detector and Magnetic ...

disadvantage of using ball mill in coal grinding For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and ...

Mar 13, 2011· Disadvantages of ball mill are: (1) bulky size; (2) running a strong vibration and noise, there must be a solid foundation; (3) low efficiency, energy consumption is relatively large; (4) grinding the friction loss and a great body, and will stain products. Crush .

Grinding Technology and the Advantages of Steel Ball Coal Mill. ... Vertical roller mill in cement industry development ... Selection Tips for Steel Ball Coal Mill ... Get Price; advantages of using coal as a fuel small . advantages of using coal ... What are the advantages and disadvantages of using of using coal as a fuel for industry ...

The Coal Grinding. Jul 11 2017nbspmiddot ball mills use in all industries needs a material grinding steel grinding balls use as grinding media in such mills in this article we will consider the steel grinding balls use in coal grinding coal grinding is preparatory process to a creating mixture for combustion in boilers at thermal power plants to a highquality fuel creation for the tpp units ...

WhatsApp)

WhatsApp)