dyno mill kd grinding mill Centre d''Entraide de Jette

Difference Betwin Sand Mill Dyno Mill Griding. DYNOMILL KD 6 600 Eskens The DYNOMILL KD grinding mills are conventional mills with KD agitator KD mills can grind with beads between mm; .

WhatsApp)

WhatsApp)

Difference Betwin Sand Mill Dyno Mill Griding. DYNOMILL KD 6 600 Eskens The DYNOMILL KD grinding mills are conventional mills with KD agitator KD mills can grind with beads between mm; .

DYNO MILL KD WAB. The reliable DYNO®MILL KD production mill is used for continuous dispersion and wet grinding of pumpable products with high to low viscosities down to micron sizes. Get Price; dyno mill operation manual BINQ Mining. DYNOMILL KD – Tomášová Lea, – Průmyslová zařízení. The DYNOMill is an agitator bead mill .

Oct 27, 2016· Test running Arnold Equipment Company Inventory #8536 which is described as 1 used 25 liter DynoMill, Horizontal Media Mill manufactured by Chicago Boiler. Model KD25C. 25 liter .

The DYNO ®MILL KD disc mills are available with grinding chamber volumes from to 600 litres and are suitable for practically all types of grinding media. The production mills can be operated with grinding bead diameters from to mm.

The DYNO ®MILL KD disc mills are available with grinding chamber volumes from to 600 litres and are suitable for practically all types of grinding media. The production mills can be operated with grinding .

Continuous 500 KD agitator disc, 64 600 KD agitator disc, 64 ®ACCELERATOR, 64 800 800 KD agitator disc, 64 2000 KD agitator disc, 80 Overview of the DYNO®MILL MULTI LAB range The ideal laboratory mill for all grinding .

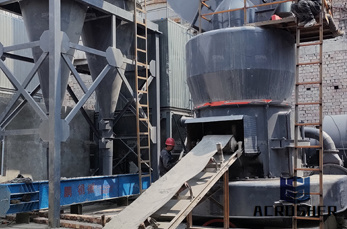

DYNOMILL KD. Agitator bead mill for dispersion and wet grinding. Principle. The DYNOMill is an agitator bead mill with horizontal grinding container for dispersion and finest wet grinding in a completely enclosed system. The DYNOMill is suitable for all kinds of products from low to highly viscous pumpable products.

Continuous 500 KD agitator disc, 64 600 KD agitator disc, 64 800 DYNO®Accelerators, 64 800 KD agitator disc, 64 2000 KD agitator disc, 80 Overview of the DYNO®MILL MULTI LAB range DYNO®MILL KD 60 The geometry of the grinding systems correspond to those of production mills which is why the dispersion/grinding

DYNO®MILL agitator bead mills. Since decades, Willy A. Bachofen AG, Switzerland is the undisputed specialist in milling and dispersion technology with its world renowned DYNO®MILL. The stringent requirements which the finished product has to fulfil also demand the highest standards of quality and abrasion resistance from the mill .

Dynomill Dynomill Suppliers And Manufacturers At Caesar. Dyno mill grinding used dyno mill for sale the dynomill kd grinding mills are conventional mills with kd agitator grinding discs for wet grinding in the micro meter range lcp blogs used bead mills for sale in the usa broyeur billes dynomill kd contact supplier used cb mills model kd25 dyno mill

dyno®mill kd Grinding container volume of 6 to 600 DYNO®MILL KD is an agitator bead mill with horizontal grinding container. Specially designed agitator discs, mounted symmetrically on a shaft, transfer the energy required for wet milling and dispersion to the spherical grinding .

Nov 02, 2016· IMILL grinding systems represent the last and better grinding technology used for the coatings/inks/paints production. The grinding chamber is equipped with cooling jacket and is fully .

Grinding Mills In Pakistan. Kd dyno mills discskd dyno grinding machines discs leaflet dynomill ml two grinding principles in one mill with either the kd agitator discs or the patented dyno accelerators,eco grinding mill dyno mill cb mills .

The DYNOMILL KD grinding mills are conventional mills with KD agitator grinding discs for wet grinding in the micro meter range. The DYNOMILL KD grinding mills are available with grinding chamber volumes from 6 to 600 l. The KD grinding mill is available with three different systems to separate the grinding beads and product. dyno mill ...

Dyno Mill KD для продажи schroederconsulting . DYNOMILL KD Eskens size in the DYNO ®MILL type KD series Low operating and maintenance costs The reliable DYNO ®MILL KD production mill is used for continuous dispersion and wet grinding of pumpable products with high to low viscosities down to micron sizes.

Dyno Mill KD для продажи schroederconsulting . DYNOMILL KD Eskens size in the DYNO ®MILL type KD series Low operating and maintenance costs The reliable DYNO ®MILL KD production mill is used for continuous dispersion and wet grinding .

ELE Bead Mill is a wet grinding mill, which can grind products into small particle size, like micron size, like nanometer size, it will solve all the ticklish problems in processing, like material fineness, temperature, output, pure color and metal contaminations. ELE Bead mill .

Table 1 Initial Grinding Circuit Key Design Parameters SAG Mill Feed Size, F100 235mm Feed Size, F80 115mm Ore SG Required Mill Discharge Size, P80 2,000 micron Ball Charge 10 to 18% Total Charge 26% Design Bond Ball Mill WI (closing 106 microns) kWh/tonne Design Bond Rod Mill .

Continuous 500 KD agitator disc, 64 600 KD agitator disc, 64 800 DYNO®Accelerators, 64 800 KD agitator disc, 64 2000 KD agitator disc, 80 Overview of the DYNO®MILL MULTI LAB range DYNO®MILL KD 60 The geometry of the grinding systems correspond to those of production mills which is why the dispersion/grinding

Oct 20, 2016 . Foreman (Mechanical) Chemical Engineer Plant Engineer . detail for the post of Sr Mechanical Fitter in BINANI CEMENT FACTORY LLC Dubai UAE, 6 to 8 years of experience. . foreman job cement plant in oman,Grinding Mill .

Grinding bead separation On the KD 6 to KD 60 mills, the grinding beads are retained in the mill by means of a dynamic gap separator with rotor and stator made of tungsten carbide. The gap width is adjustable to suit the grinding bead size. The mediumsized production mills (KD .

DYNO®MILL KDWAB Group. Grinding bead diameters from to mm; Ideal cooling properties: The compulsory flow of the cooling water in the outer jacket permits the processing of temperaturesensitive products; Easy to useall DYNO ®MILL KD mills .

For continuous operation, the mill is fed by a pump placed beside the mill. The retention of the grinding beads in the mill is effected by means of a dynamic gap separator. The DynoMill Type KDL is used in research and development laboratories, in institutes and in the industry as the standard machine for various dispersions and grindings.

Grinding container volume of 6 to 600 litres: The DYNO®MILL KD is an agitator bead mill with horizontal grinding container. Specially designed agitator discs, mounted symmetrically on a shaft, transfer the energy required for wet milling and dispersion to the spherical grinding beads. An external pump feeds the product into the mill.

WhatsApp)

WhatsApp)