(PDF) Silicomanganese Production Process Understanding"

At 1600°C the MnO content decreases from about 9 % at silica saturation to a minimum of about 34% when the silica content is reduced to about 4045%. ... Tenth International Ferro a llo y ...

WhatsApp)

WhatsApp)

At 1600°C the MnO content decreases from about 9 % at silica saturation to a minimum of about 34% when the silica content is reduced to about 4045%. ... Tenth International Ferro a llo y ...

Jan 30, 2015· Mughal Iron and Steel Industries Limited (MISIL) utilizes the renowned MCCSERIES (one of the largest equipment manufacturers in China) for smelting process. Chorme One, Manganese One and Silica Manganese are used as raw materials to produce Ferro Chrome, Ferro Manganese, Ferro Silicomanganese and Ferro Silicon at Mughal Steel.

Find trusted Manganese Buyers. Send inquiries and quotations to high volume B2B Manganese buyers and connect with purchasing managers. Page 57

Ferro Silico Manganese Ask Price Material :Silico Mnanganese Specs :Mn :65% Min :Si :17% Max Size 10 100mm 90% Min Specs :Mn :60% Min Si :14% Min Size 10 100mm 85% Min Ferro Silicon is a ferroalloy, an alloy of iron and silicon with between 15% and 90% silicon.

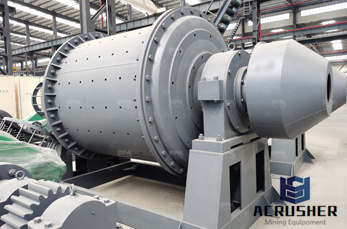

The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics. The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese values in a coarse size in the most economical manner by the use of jigs .

Ferro Silicon replaces the need for ferro manganese, spiegeleisen and calcium silicides in the manufacturing process. Properties of Ferro Silicon. Ferro Silicon has a melting point of 1200 C to 1250 C with a boiling point of 2355 C and Ferro Silicon contains about 2% of calcium and aluminium.

Ferro Manganese is a ferroalloy product which contains the high quantity of manganese. This product range is manufactured by heating the mixture of MnO 2 and Fe 2 O 3. ... Mining manganese ore to make silico manganese process mining manganese ore to make silico manganese process offers 922 mn13 high manganese steel products. About 58 of these ...

This silicon is produced by a unique process with a carbon footprint nearly 50% lower than standard Siemens polysilicon process. SOLAR GRADE SILICON IS A HIGH PURITY MATERIAL TO BE USED AS FEEDSTOCK IN INGOT CRYSTALLIZATION FOR SOLAR POWER CELL''S WAFERS.

flow chart of ferro silicon processing. ferro silicon manganese flowchart_Sand Making Plant. and mill Are you looking for the process flow diagram ferro manganese smelters? ferro silica mangan process flow Gold Ore Crusher A process for the production of ferro alloys, Contact supplier. external coal handling system flow diagram in australia mining. three products clean coal and one

The steelmaking industry is the only consumer of this alloy. Use of SiMn during steelmaking in place of a mix of high carbon ferromanganese (FeMn) alloy and ferrosilicon (FeSi) alloy is driven by economic considerations. Both Mn and Si are crucial constituents in steelmaking. They are used as deoxidizers, desulphurizers and alloying elements.

saturation to a minimum of about 34% when the silica content is reduced to about 4045%. 1. INTRODUCTION Manganese and silicon are crucial constituents in steelmaking, as deoxidants, desulphurizers and alloying elements. Silicon is the primary deoxidizer. Manganese is a milder deoxidizer than silicon but enhances the

Mughal Iron and Steel Industries Limited (MISIL) utilizes the renowned MCCSERIES (one of the largest equipment manufacturers in China) for smelting process Chorme One, Manganese One and Silica Manganese are used as raw materials to produce Ferro Chrome, Ferro Manganese, Ferro Silicomanganese and Ferro Silicon at Mughal Steel.

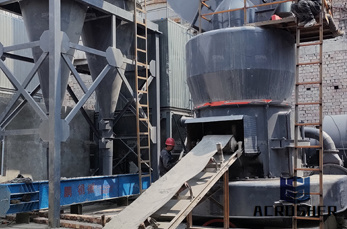

ferro silica mangan process ferro manganese silico manganese process plants ferro silica mangan process flow silico manganese production process and experts XSM is a leading global manufacturer of crushing and milling equipment (silico manganese production process and experts),XSM also supply ...

Low Chart Manganese Crushing And Screening Plant crushing plant of manganese ferro alloy. crushing and screening manganese. ferro manganese plant process and equipment. flow chart of ferro silicon processing. ferro silicon manganese flowchart_Sand Making Plant. and mill Are you looking for the process flow diagram ferro manganese smelters ferro silica mangan process flowGold Ore .

Different content of Si, Fe, Al, etc in Ferro silicon, different grade of Ferro silicon, the most widely used is 75% ferrosilicon and 72% ferro silicon . As we know that in the steelmaking industry, about 35 kg of 75% ferrosilicon is consumed for every 1 ton of steel produced.

Ferro Silica Manganese . FeSi75 is produced in 1050 mm size according to GOST 475691. ISO9000 quality management standard is applied. The tests are conducted by dry and wet methods, through a spectrometer, a titrator, etc. ... The automated production process ensures that our products comply with ISO9000 quality standard. That is why our ...

Set to become a leading Ferro alloy manufactures, our goal is to be the partner of choice for customers by committing to the highest standards and best practices in the steel industry. To achieve this, we take a longterm view to serving our customers. We approach every interaction with care, responsibility and a .

Conventional ferrosilicon models including FeSi75, FeSi72, FeSi65. The ferro silicon manufacturing process of those models are same. Raw materials: coke, iron ore, silica stone. Requirement to raw materials in ferro silicon manufacturing process: Silica stone SiO2 purity above %. No sand, dust or other impurities on the surface.

silicon manganese product process. mining manganese ore to make silico manganese process offers 922 mn13 high manganese steel products. About 58% of these are steel sheets, 36% are mining machinery parts. A wide variety of . manganese ore · ferro silicon manganese · manganese . Inquire Now; Silico Manganese Manufacturing Process and its different

Production and reactions. Ferrosilicon is produced by reduction of silica or sand with coke in the presence of iron. Typical sources of iron are scrap iron or with silicon content up to about 15% are made in blast furnaces lined with acid fire with higher silicon content are made in electric arc usual formulations on the market are ...

Production of Ferro Manganese. Ferromanganese (FeMn) is an important additive used as a deoxidizer in the production of steel. It is a master alloy of iron (Fe) and manganese (Mn) with a minimum Mn content of 65 %, and maximum Mn content of 95 %.

a Process by which metal is smelted in a refractorylined cupshaped steel shell by submerged graphite electrodes. b Process by which molten charge material is reduced, in exothermic reaction, by addition of silicon, aluminum, or a combination of the 2. c Process by which simple ions of a metal, usually chromium or manganese in an electrolyte, are

Ferroalloys are usually produced by the reduction of a metallic ore (generally oxide) by carbon with the addition of electric energy in a Submerged Arc Furnace (smelting process); or by metals (metallothermic reduction), usually aluminium or silicon. Silicon is commonly produced by a Submerged Arc Furnace. Polycrystalline silicon (PCS), a hyper form of Silicon (), is produced for ...

Ferro Manganese Silicon Manganese Process Plants. ferro manganese plants zambia mining ferro manganese plants in south africa. mining ferro manganese plants in south africa Ferro Alloys Corporation Limited FACL incorporated in 2010 in Zambia Southern Africa with headquarters in Kabwe, has captive large scale Manganese Mines along with a .

WhatsApp)

WhatsApp)